Explore the Benefits of Fanless Industrial PCs Today

Understanding Fanless Industrial PCs: A Comprehensive Overview

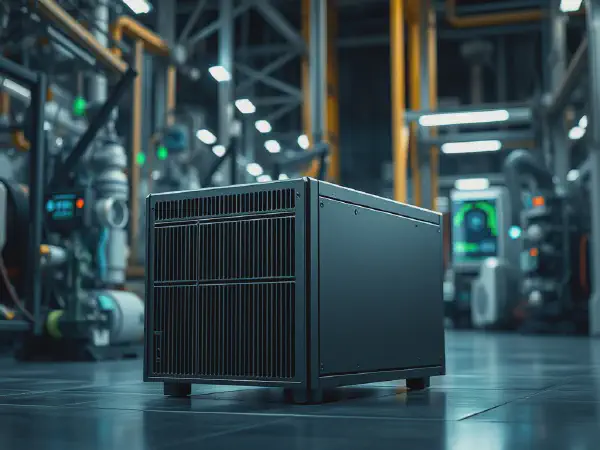

Fanless Industrial PCs are specialized computing solutions designed for robust performance in demanding environments. Unlike traditional PCs, these devices operate without fans, utilizing advanced thermal management techniques to dissipate heat effectively. Their unique design and functionality make them ideal for a variety of industrial applications, ensuring reliable operations even in extreme conditions.

The evolution of Fanless Industrial PCs has been marked by advancements in technology that allow for powerful computing capabilities without the need for active cooling. This is particularly important in industries where dust, moisture, and high temperatures can pose serious risks to standard PC components. By eliminating fans, Fanless Industrial PCs offer enhanced protection against contaminants, leading to improved system longevity and reliability.

To streamline your workflow, take advantage of the latest qnavigator download for improved navigation and control.

With an increasing emphasis on noise reduction in industrial environments, Fanless Industrial PCs stand out as an excellent choice. Their silent operation not only helps maintain a conducive working environment but is also essential in applications where sound levels must be kept to a minimum, such as in medical settings or close to sensitive machinery. These devices deliver efficient, high-performance computing without compromising on operational stealth.

For optimal performance in automated environments, an industrial mini pc can significantly enhance processing capabilities.

Fanless Industrial PCs are also recognized for their energy efficiency. With a focus on low power consumption, they help companies reduce their energy bills while minimizing heat generation. This not only contributes to lower operational costs but also supports sustainability initiatives by decreasing the carbon footprint associated with industrial computing.

As industries increasingly rely on sophisticated technology for automation and data collection, Fanless Industrial PCs are becoming integral to applications that require consistent performance under temperature-sensitive conditions. Their ability to function effectively without fans makes them well-suited for scenarios where traditional solutions may fail due to overheating or contamination.

Advantages of Fanless Industrial PCs

One of the primary advantages of Fanless Industrial PCs is their improved reliability in harsh environments. By eliminating moving parts such as fans, these systems are less likely to experience mechanical failures, leading to higher operational uptime and decreased maintenance costs. They are engineered to withstand extreme temperatures, vibrations, and exposure to dust and moisture, making them an ideal choice for factories and outdoor settings.

The durability and efficiency of an industrial motherboard are crucial for ensuring uninterrupted operation in harsh conditions.

Reduced noise levels are another significant benefit of Fanless Industrial PCs. In settings where noise can be distracting or detrimental—such as hospitals, laboratories, and quiet factories—these devices provide a peaceful computing experience. Users can perform tasks without the disruptive hum of traditional fans, allowing for better concentration and productivity.

Additionally, the longer lifespan of Fanless Industrial PCs, resulting from fewer moving parts, translates to better return on investment for businesses. With minimal wear and tear, these systems can function effectively for years, reducing the need for periodic replacements commonly associated with traditional PCs. This durability is particularly advantageous in high-stakes environments like aerospace or automotive manufacturing.

Fanless Industrial PCs are designed with energy efficiency in mind, resulting in lower operational costs. By utilizing low-power processors and optimizing power consumption, these systems can run continuously without the large energy costs typically associated with traditional PCs. This makes them particularly appealing for businesses keen on sustainability and reducing their overall energy requirements.

Enhanced performance in temperature-sensitive applications is another hallmark of Fanless Industrial PCs. These systems excel in environments where temperatures fluctuate, maintaining optimal functionality even in extreme conditions. Their passive cooling mechanisms ensure consistent performance and reliability, which are crucial in industries such as food processing, pharmaceuticals, and chemical production.

Applications of Fanless Industrial PCs

One of the prominent applications of Fanless Industrial PCs is in automation and control systems. Their resilience allows them to function as control units in manufacturing lines, overseeing processes, and managing data without interruption, thus enhancing productivity and efficiency in factories.

Deployment in outdoor and mobile applications is another area where Fanless Industrial PCs shine. For instance, in smart transportation systems, these devices are utilized in vehicles, rail operations, and logistics, where traditional fan-based systems would be vulnerable to dust and environmental factors.

Moreover, integration in medical equipment is becoming increasingly common. In hospitals and medical devices, the need for silent, compact, and reliable systems is crucial. Fanless Industrial PCs can power critical monitoring systems and diagnostic equipment without adding noise or risk of contamination from moving parts.

In the transportation and logistics sector, Fanless Industrial PCs are reliable solutions for data collection, inventory management, and real-time tracking. Their ability to operate in varied environments, whether on factory floors or in delivery vehicles, ensures seamless operations across the logistics chain.

Additionally, Fanless Industrial PCs play a vital role in retail and point-of-sale systems. Their compact size, low noise emission, and robustness make them perfect for retail environments, where they can manage transactions and inventory without the distractions or disruptions caused by traditional computing systems.

Design Considerations for Fanless Industrial PCs

Thermal management techniques are crucial in the design of Fanless Industrial PCs. These systems often employ heat sinks, thermal conductive materials, or innovative casing designs to ensure effective heat dissipation, which is vital for maintaining performance and system integrity under load.

Choosing the right materials for durability is another important design consideration. Fanless Industrial PCs are often constructed from rugged materials that can withstand abrasion, moisture, and temperature variations, ensuring that they continue to perform under adverse conditions.

The form factor and space-saving designs are also significant aspects of Fanless Industrial PCs. Due to their fanless architecture, these systems can be compact, making them suited for environments where space is limited, such as control cabinets or mobile applications.

Customization options for specific industries allow manufacturers to tailor Fanless Industrial PCs to meet unique requirements. From the choice of connectors and interfaces to specific housing configurations, customization ensures that the systems meet the operational standards of diverse sectors.

Understanding IP ratings for protection can further guide the design of Fanless Industrial PCs. Higher IP ratings indicate better resistance against dust and moisture, necessary for devices operating in industrial environments. This understanding is essential for selecting the right solution for particular applications.

Future Trends in Fanless Industrial PCs

Advancements in thermal technology will continue to play a significant role in the evolution of Fanless Industrial PCs. Ongoing research aims to develop even more efficient cooling solutions that further enhance performance while keeping energy consumption low.

The integration of Fanless Industrial PCs with IoT and smart systems is also a growing trend. As industries move towards smart automation, these devices will be leveraged to gather and process data from connected machines, leading to improved decision-making and operational efficiencies.

The rise of edge computing applications signifies another shift in the industrial landscape. Fanless Industrial PCs can serve as gateways, processing data at the edge of the network and reducing latency while enhancing the real-time capabilities of industrial systems.

Sustainability in industrial computing is becoming increasingly important, and Fanless Industrial PCs are well-positioned to lead this transition. Their low power consumption and longer lifespans contribute to reducing waste and energy use, aligning with broader corporate sustainability goals.

Emerging markets for fanless solutions, such as renewable energy or smart cities, represent growth opportunities for Fanless Industrial PCs. As industries become more technology-driven, the demand for reliable, efficient, and environmentally friendly computing solutions will only continue to increase.

Comparison with Traditional PCs

When comparing Fanless Industrial PCs with traditional PCs, benchmarking performance metrics reveals significant advantages. Fanless systems often utilize energy-efficient processors that outperform standard chips in specific tasks while consuming less power and generating less heat.

Heat dissipation techniques used in traditional PCs rely heavily on fans and active cooling systems, which can introduce failure points and maintenance concerns that Fanless Industrial PCs avoid altogether by utilizing passive cooling methods.

Maintenance requirements and costs also differ considerably. While traditional PCs require regular dusting and potential fan replacements, Fanless Industrial PCs demand far less upkeep, translating to lower ongoing maintenance costs and simpler operational processes.

Longevity and reliability differences highlight the advantages of Fanless Industrial PCs. With no fans to wear out, these systems typically exhibit longer operational lifetimes, making them more reliable and cost-effective over time compared to their traditional counterparts.

Finally, energy consumption comparisons show that Fanless Industrial PCs provide greener solutions than traditional PCs. Their optimized designs minimize energy use without compromising performance, aligning them closely with the growing demands for sustainability in industrial settings.